This method describes how to mill grain or malt to produce fine or coarse grist.

Malt intended for use in beer brewing or elsewhere in the food industry

Malt is ground between two horizontally positioned, grooved discs. The lower disc is driven by an electric motor and rotates at approx. 1500 rpm; the upper disc is fixed and therefore does not move. During the milling process, the malt migrates from the center of the discs to the outer edge, where the grist falls through an outlet spout into a grist beaker.

The gap between the discs can be adjusted by turning a socket head screw on a calibrated ring bearing scale markings. The scale on the calibrated ring ranges from 0 to 20, with each scale division corresponding to a gap between the discs of 0.10 mm. Each scale division is subdivided into five smaller divisions; each of the smaller marks is equivalent to 0.02 mm. Two gap adjusting rings ensure reproducible mill settings.

Whole hops intended for use in beer brewing or elsewhere in the food industry

Evaluation of the appearance of hop cones is performed through visual and manual inspection.

Malt intended for use in beer brewing or elsewhere in the food industry

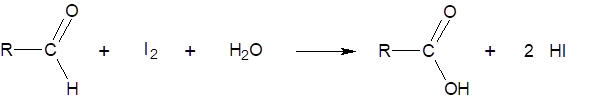

The aliquot of an extract of malt is added to a buffered starch solution and allowed to stand for exactly 30 min at 20 °C. Then, the maltose – formed primarily from the starch through the action of the β-amylase – is measured using iodine and is determined according to the following chemical reaction:

This method describes the determination of color of (Congress) wort using color discs.

Malt intended for use in beer brewing or elsewhere in the food industry

The determination of the color of the Congress wort is carried out under defined lighting conditions through a visual comparison of the wort color with the appropriate color discs. Please note that several individuals should perform the color measurement if possible.

Barley intended for the production of malt is to be evaluated on the basis of the characteristics described below.

visual assessment

Hops and hop products intended for use in beer brewing or elsewhere in the food industry

The respective constituents of hops are not uniformly distributed throughout the cones. The aroma compounds and bitter substances are found in the lupulin glands inside the cone, adhering to the cone bracteoles near the strig. The polyphenols, on the other hand, are found in the bracts, bracteoles and stems. In order to reliably analyze the constituents of hop cones, homogenization of the sample is required. For this purpose, the cones are ground and the sample is divided.